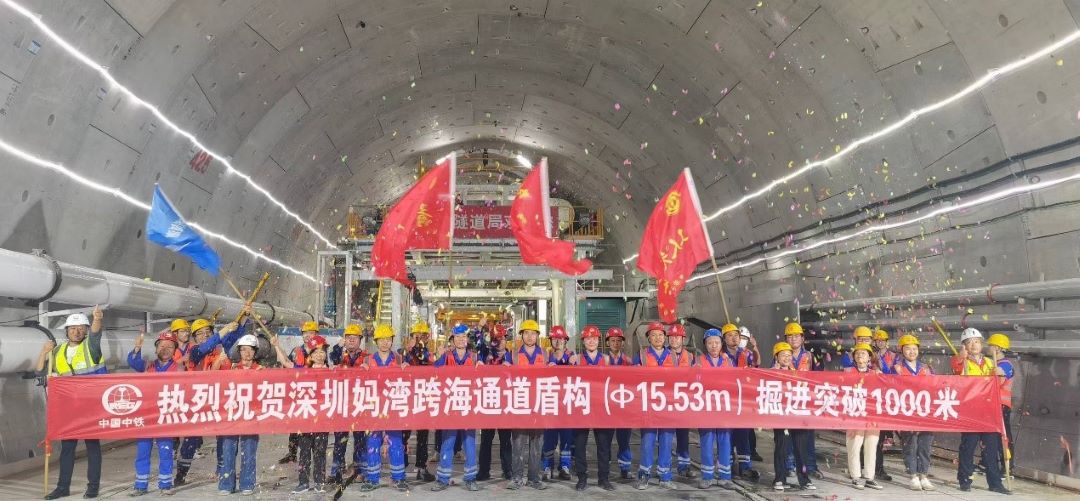

【Domestic News】The Largest Diameter Subsea TBM (15.53m) under Construction in China – Excavation of the Right Line of Mawan Cross-sea Passage Exceeds 1000m

On April 18, the TBM tunneling of the right line of Shenzhen Mawan Cross-sea Passage project undertaken by China Railway Tunnel Group(CRTG) successfully broke through 1000 meters.

Being the first subsea tunnel in Shenzhen City, Mawan cross-sea passage by CRTG is also the largest diameter subsea TBM project under construction in China. The TBM section on the right line of Mawan subsea tunnel extends 2063m, excavated by a 15.53m diameter super-large diameter TBM, named "Mawan". And the TBM construction faces huge challenges with exceeding 50% proportion of uneven soft and hard rock strata along the line and the maximum full-section hard rock strength up to 193Mpa.

The "Mawan" TBM launches from Dachanwan port area, crosses the sea section and arrives at Qianhai industrial area. Within the 1000m excavation mileage, CRTG’s project team overcame the high risk of TBM launching under shallow soil, and solved major challenges including TBM drive control under complex strata in reclamation area, serious TBM cutter wearing and loss in full-section hard rock strata and uneven strata and etc.

The project team, by improving the TBM launching structure and shear resistance of segment concave convex tenon structure, ensured the safety of TBM launching and the quality of segment assembly. In view of the abnormal tool wear caused by the composite strata, the project team statistically summarized and analyzed cutter wear conditions during TBM boring, and optimized the cutter installation, thus effectively reduced the abnormal wear and improved the equipment utilization.

Relying on the smart TBM engineering big data platform, the Mawan cross-sea project team of CRTG achieves real-time intelligent monitoring and automatic early warning, which can monitor the tunneling parameters at the mobile terminal at all times and covering all sections. A full-time "parameter analyst" is assigned for TBM tunneling to collect information for geological research and judgment, slag sample analysis, cutter monitoring and sound collection, so as to realize research, judgment and disclosure on each ring. Under the stress against COVID-19, the project has achieved a monthly progress of 170 meters.

CRTG International

Avic Tower,

East Third Ring Road B 10,

Chaoyang District, Beijing City, P. R. China

Email: info@crtg.cn

CRTG

No.2 (Self-Made), West Side of Gongye 4th Road,

Mingzhuwanqibu Area,

Nansha District,

Guangzhou City, Guangdong Province, P. R. China

Tunnelling to Link the World

-

ꁸ Top

-

ꂅ 88888888

-

ꀥ QR code